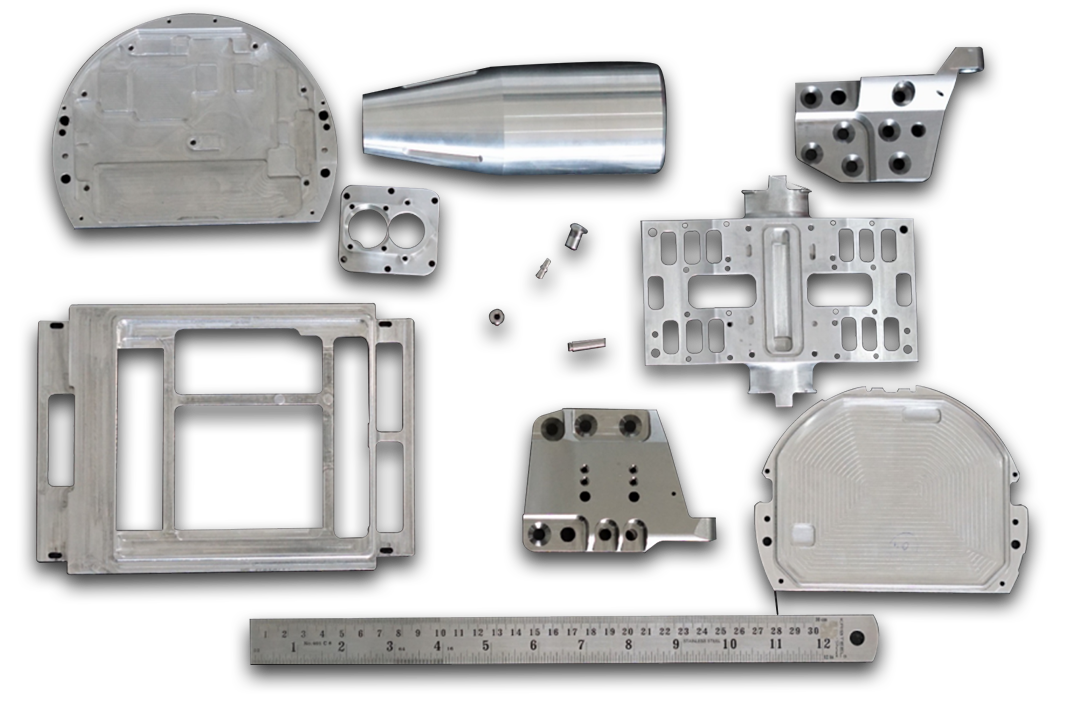

Aeropact is equipped with the latest high-speed CNC machines capable of heavy workloads and fast, efficient metal removal ensuring accuracy and meeting all quality standards.

| METALS | SERVICES |

|---|---|

| Aluminum | Stocking Programs |

| Bronze | Special Processing |

| Brass | Benchtop Assemblies |

| Copper | |

| Steel Alloys | |

| Stainless Steel | |

| Titanium |

Spread across 2 acres with an airport and National Highway close by, Aeropact began with a 6,500 sq. ft. manufacturing facility. With ample room for growth, our facility is expandable up to 5 times its current size and capacity, allowing for the introduction of new machinery and new business opportunities. Our close proximity to the Highway and the Airport helps us to reduce our turnaround on finished products and minimize our costs.

Our manufacturing floor is specifically designed for optimal production, utilizing a cell manufacturing setup on the floor that can be arranged to meet the demands of any project. The location is adequately sized to accommodate both projects large and small.